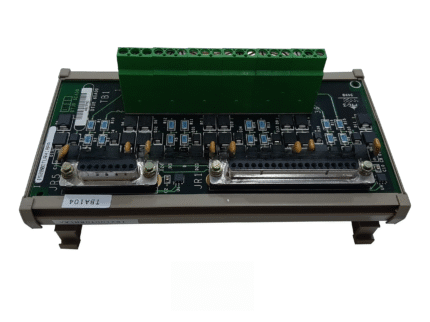

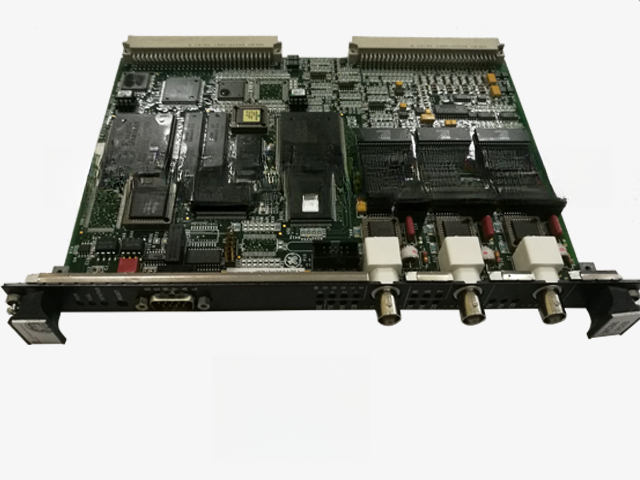

IS215VCMIH2BF

IS215VCMIH2BF

The IS215VCMIH2BF is a high-performance Communication Interface Module designed for GE’s Mark VI turbine control systems. It plays a vital role in managing communication between the control system and the VME backplane, ensuring fast and reliable data transmission. Engineered for demanding industrial environments, it supports high-speed networking and secure data exchange protocols, making it an integral component in power plant automation and turbine control operations.

Description

The IS215VCMIH2BF Communication Interface Module is a robust and essential hardware component used in the GE Mark VI Speedtronic control system. Designed to support VME-based architectures, this module serves as a bridge between the control processors and I/O networks, facilitating high-speed, reliable data transmission. Its role is crucial in ensuring uninterrupted communication between various control sections of the turbine system, which directly affects the efficiency, safety, and responsiveness of the entire setup.

This VCMI module is primarily used to manage IONet communication, which is the proprietary GE communication protocol for data flow between controllers, I/O modules, and other system components. It acts as the bus master for the VME backplane, enabling synchronized control across the board. It supports multiple connections and ensures deterministic data transmission, a necessity in mission-critical power generation environments.

The IS215VCMIH2BF is equipped with diagnostic LEDs to assist in quick identification of faults, communication failures, or operational states. Its firmware is upgradeable, and it features multiple communication ports including Ethernet and serial interfaces. Designed to withstand industrial temperatures, it offers ruggedness, high EMI resistance, and dependable longevity in power generation plants.

Whether you are upgrading, replacing, or configuring your turbine control system, the IS215VCMIH2BF helps maintain optimal communication performance while ensuring system stability. This module is widely compatible with a range of Mark VI configurations, offering flexibility and reliability in real-time control scenarios. It is ideal for use in gas and steam turbines where operational integrity and quick decision-making are critical.

Key Features:

Enables communication between control processors and IONet

VME bus master functionality for high-speed data handling

LED status indicators for diagnostics and troubleshooting

Durable design for industrial environments

Compatible with GE Mark VI turbine control systems

Supports hot-swap replacement and firmware upgrades

Offers Ethernet and serial communication interfaces

Contact Information:

Evaflux Private Limited

📞 Phone: +91 7303573946

📧 Email: support@evaflux.com

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

Reviews

There are no reviews yet.