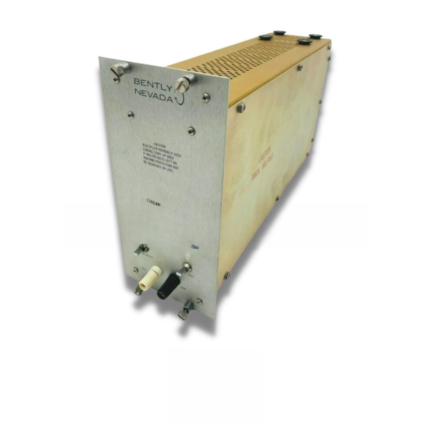

3500/60 – Temperature Monitor

3500/60 – Temperature Monitor

Bently Nevada 3500/60 – Advanced multi-channel temperature monitoring module for critical machinery protection and predictive maintenance.

Description

The Bently Nevada 3500/60 Temperature Monitor is an advanced rack-based module specifically engineered to provide precise, continuous temperature measurement and protection for critical industrial machinery. As part of the trusted Bently Nevada 3500 Series condition monitoring system, this module plays a key role in safeguarding equipment performance, preventing unplanned downtime, and extending asset lifespan.

The 3500/60 is designed to accept multiple temperature sensor inputs, including Resistance Temperature Detectors (RTDs) and Thermocouples (TCs), offering exceptional flexibility in monitoring different machine components. It can monitor bearing temperatures, winding temperatures, and other thermal conditions in turbines, compressors, motors, generators, and pumps.

The 3500/60 accepts a variety of temperature sensor inputs, including Resistance Temperature Detectors (RTDs) and Thermocouples (TCs), making it suitable for monitoring diverse applications such as bearing housings, motor windings, turbine casings, compressor stages, and pump seals. Each channel can be configured independently, allowing the flexibility to adapt to specific operational industrial environments.

One of the standout features of the 3500/60 is its advanced alarm processing capability. Operators can set multiple alarm setpoints for each channel — including Alert and Danger levels — to detect abnormal temperature changes early. This proactive monitoring approach supports predictive maintenance programs, allowing plant personnel to address potential issues before they escalate into unplanned outages.

Equipped with advanced alarm processing, the 3500/60 allows operators to configure multiple alarm setpoints for each channel, enabling early detection of abnormal temperature trends before they escalate into critical failures. It integrates seamlessly with the rest of the 3500 system, providing real-time data to operators via the rack display or connected control systems.

Its rugged industrial design ensures stable operation in demanding environments, with high immunity to electrical noise, mechanical vibration, and temperature fluctuations. The module supports predictive maintenance strategies by allowing continuous monitoring and historical data logging for trend analysis.

Whether deployed as part of a new system or retrofitted into existing Bently Nevada monitoring setups, the 3500/60 delivers reliable, precise, and actionable temperature measurement essential for protecting mission-critical assets.

Key Features

Accepts RTD and Thermocouple inputs

Multi-channel temperature monitoring

Configurable alarm setpoints for each channel

Real-time integration with Bently Nevada 3500 system

Rugged design for harsh industrial conditions

Ideal for turbines, compressors, motors, and generators

Supports predictive maintenance and trend analysis

Contact Information

Evaflux Private Limited

📞 Phone: +91 7303573946

📧 Email: support@evaflux.com

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

Reviews

There are no reviews yet.