3500/22M – Transient Data Interface Module

3500/22M – Transient Data Interface Module

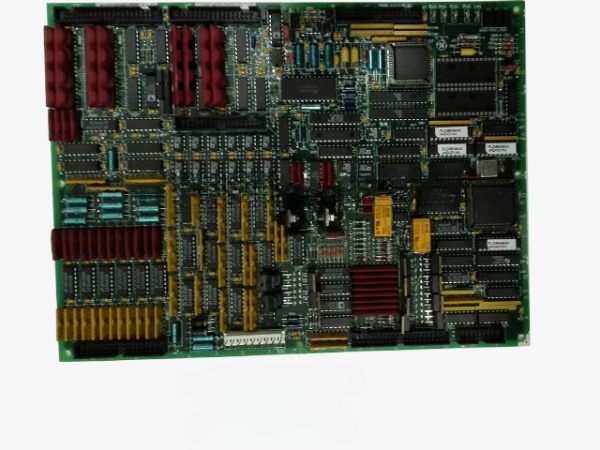

The Bently Nevada 3500/22M Transient Data Interface Module acts as the central processing unit of the 3500 monitoring system, enabling seamless data acquisition, configuration, and communication. It supports real-time and transient data capture for advanced diagnostics and machinery protection.

Description

The Bently Nevada 3500/22M – Transient Data Interface (TDI) Module is the heart of the 3500 Series Machinery Protection System, combining the functionality of a communication processor with the power of advanced data acquisition. As the main interface between the monitoring modules and software systems, the 3500/22M TDI is essential for capturing and analyzing both static and transient machinery data.

This intelligent module not only handles communication with configuration and condition monitoring software (such as System 1®) but also stores high-resolution transient data that is vital for machinery diagnostics. Unlike standard processors, the 3500/22M provides buffered sensor output and delivers detailed waveform and spectral data during abnormal machine conditions like startups, shutdowns, or trips.

Ideal for use in power generation, oil and gas, petrochemicals, and other industrial environments, the 3500/22M supports a wide range of communication protocols including Ethernet and proprietary communication links. It enables centralized configuration, real-time monitoring, and easy integration with DCS or SCADA systems.

The module is fully compatible with other Bently Nevada 3500 series modules and fits into the leftmost slot of the rack. Its plug-and-play functionality ensures minimal installation time and reliable performance in mission-critical environments. Additionally, the 22M offers enhanced memory capacity and faster data throughput than its predecessors, making it an ideal solution for plants seeking actionable insight from rotating machinery.

Whether your goal is to prevent unexpected machinery failures or improve your predictive maintenance strategies, the Bently Nevada 3500/22M TDI Module delivers the advanced diagnostic capabilities you need.

⭐ Key Features:

✅ Central Processor for 3500 System: Acts as the main interface between the system and software.

✅ Transient Data Capture: Stores high-resolution data during machine events (startup, shutdown, trips).

✅ System 1® Compatibility: Enables condition monitoring and remote diagnostics.

✅ Buffered Sensor Output: For in-depth analysis of machine health parameters.

✅ Supports Dual Communication Ports: Ethernet, Modbus TCP/IP, and serial options.

✅ Plug-and-Play Installation: Fits into the leftmost slot of the 3500 rack.

✅ High Reliability: Engineered for harsh industrial environments.

✅ Backward Compatibility: Works with standard 3500 I/O modules and transducers.

📞 Contact Information:

Evaflux Private Limited

📍 India

📞 Phone: +91 7303573946

📧 Email: support@evaflux.com

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

Reviews

There are no reviews yet.