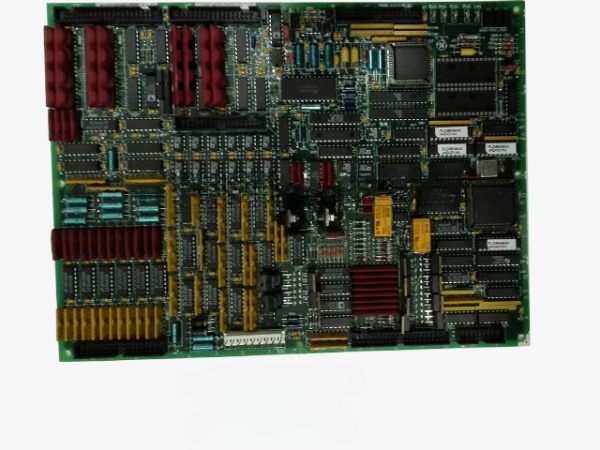

136188-02 – Ethernet/RS232 Modbus I/O Module

136188-02 – Ethernet/RS232 Modbus I/O Module

The Bently Nevada 136188-02 Ethernet/RS232 Modbus I/O Module provides dual communication options for integrating 3500 systems with plant control networks, ensuring reliable data exchange.

Description

The 136188-02 Ethernet/RS232 Modbus I/O Module from Bently Nevada is an advanced communication interface designed for the 3500 Machinery Protection System, enabling seamless data exchange between the monitoring rack and plant control networks. Supporting both Ethernet and RS232 Modbus communication protocols, this module ensures reliable integration with a wide range of Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) platforms, and other industrial automation systems.

The 136188-02 facilitates the transfer of static and dynamic machinery data, alarm events, and configuration settings. By providing plant operators with real-time condition monitoring information, it helps detect abnormal machine behavior early, enabling corrective action before costly failures occur.

Its dual communication capability — Ethernet for high-speed networking and RS232 Modbus for robust serial communication — offers flexibility in system design and ensures compatibility with both modern and legacy systems. The module supports Modbus TCP/IP for Ethernet connections and Modbus RTU for RS232 links, delivering industry-standard data exchange.

Built to operate reliably in demanding industrial environments, the 136188-02 features a rugged design that withstands temperature fluctuations, vibration, and humidity. It is ideally suited for oil & gas plants, petrochemical facilities, power generation stations, and manufacturing operations where uptime and data reliability are essential.

As part of the Bently Nevada 3500 system, this I/O module plays a vital role in predictive maintenance strategies, improving asset reliability, and reducing unplanned downtime.

Evaflux Private Limited supplies genuine Bently Nevada 136188-02 Ethernet/RS232 Modbus I/O Modules with fast delivery, competitive pricing, and expert technical support to ensure your monitoring systems remain fully operational.

Key Features

Part of the Bently Nevada 3500 Machinery Protection System.

Supports Ethernet Modbus TCP/IP and RS232 Modbus RTU communication.

Enables data transfer between the 3500 rack and control systems.

Handles real-time machine data, alarm events, and configuration settings.

Dual communication options for modern and legacy system integration.

Rugged design for harsh industrial environments.

Reliable operation for continuous machinery monitoring.

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

.webp)

Reviews

There are no reviews yet.