IS220PPROH1A, REV E

IS220PPROH1A, REV E

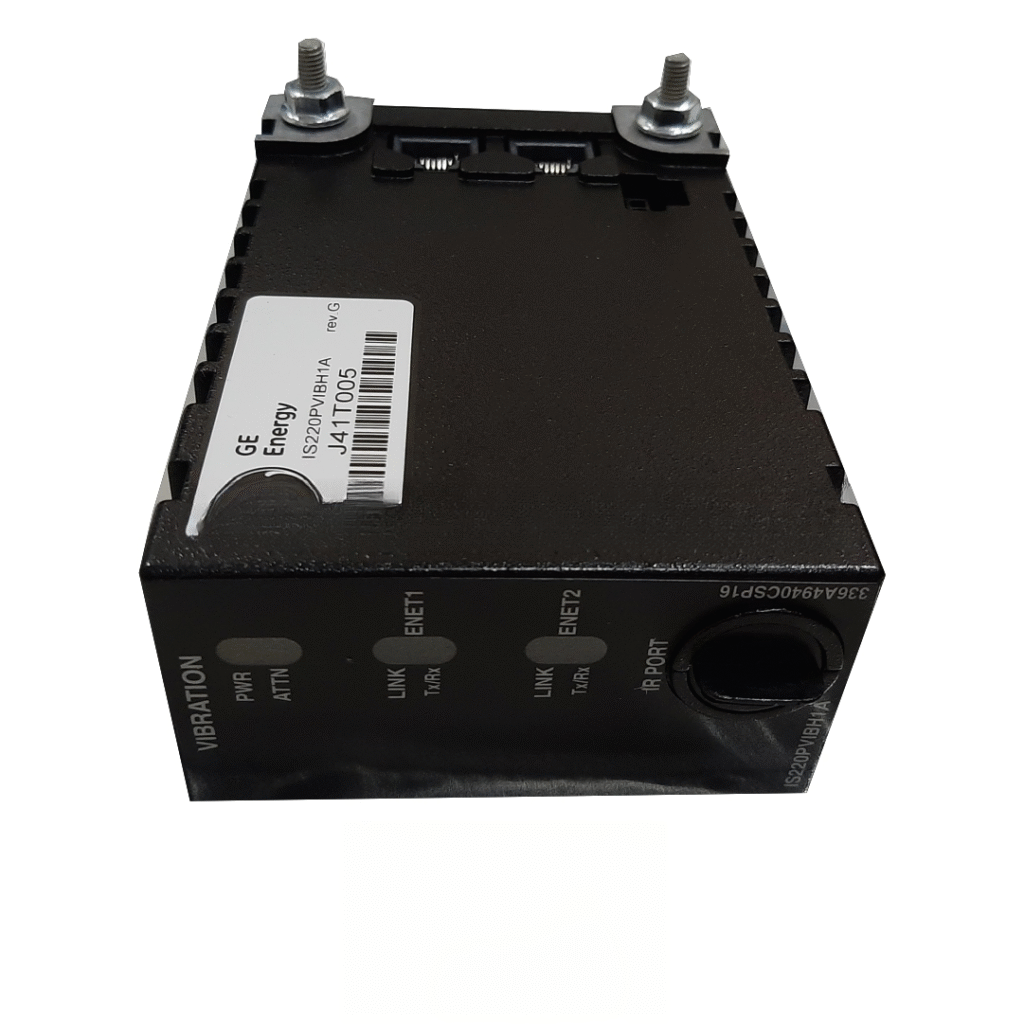

The IS220PPROH1A REV E is a Precision Protection Module designed for integration with GE Mark VIe control systems. It delivers high-speed protection, trip logic, and input/output management for critical rotating machinery applications.

Description

The IS220PPROH1A REV E is a Precision Protection Module developed to enhance the reliability and safety of high-value assets in power generation and industrial automation. As part of the GE Mark VIe control system family, this module is engineered to execute high-speed protection and monitoring functions required for turbines, compressors, and other rotating machinery.

Built on GE’s advanced I/O platform, the IS220PPROH1A offers deterministic control and protection functions by capturing critical process variables in real time. It provides robust interface capabilities for discrete and analog signals, integrating seamlessly with the control network via the high-speed IONet protocol. The module is capable of managing trip logic, monitoring speed and overspeed conditions, and performing fault isolation, all with high accuracy and responsiveness.

The IS220PPROH1A includes built-in diagnostics, real-time data monitoring, and status LEDs for operational transparency. With dual-redundant IONet connectivity and hot-swappable design, the module ensures uninterrupted operations and simplified maintenance even during active system runtime. These features are essential for applications where equipment uptime and operator safety are mission-critical.

This module integrates with ToolboxST software, enabling efficient configuration, firmware upgrades, alarm management, and event logging. It supports SIL-rated applications and adheres to strict industrial standards for electromagnetic compatibility, thermal endurance, and vibration resistance.

The IS220PPROH1A’s ability to reliably process protection-related logic independently from the main controller adds a layer of safety, making it suitable for modern turbine protection schemes in both gas and steam turbine environments. Its precise response time helps prevent equipment damage and allows operators to address anomalies proactively.

Ideal for applications within GE Mark VIe environments, the IS220PPROH1A provides dependable machine protection, streamlined diagnostics, and increased operational efficiency. Its modular structure and compatibility with a wide range of terminal boards make it a flexible and scalable solution for various plant configurations.

Key Features:

Designed for GE Mark VIe turbine control systems

High-speed protection and precision logic execution

Interfaces with analog and discrete signals

IONet-based communication with dual redundancy

Real-time diagnostics and health monitoring

Hot-swappable module for simplified maintenance

Integrates with ToolboxST for setup and alarms

Supports SIL-rated protection applications

Built-in trip logic for machinery safety

Rugged design for harsh industrial environments

Contact Information:

Evaflux Private Limited

📞 Phone: +91 7303573946

📧 Email: support@evaflux.com

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

Reviews

There are no reviews yet.