IS200TTURH1BED – Protection Input turbine terminal Board

IS200TTURH1BED – Protection Input turbine terminal Board

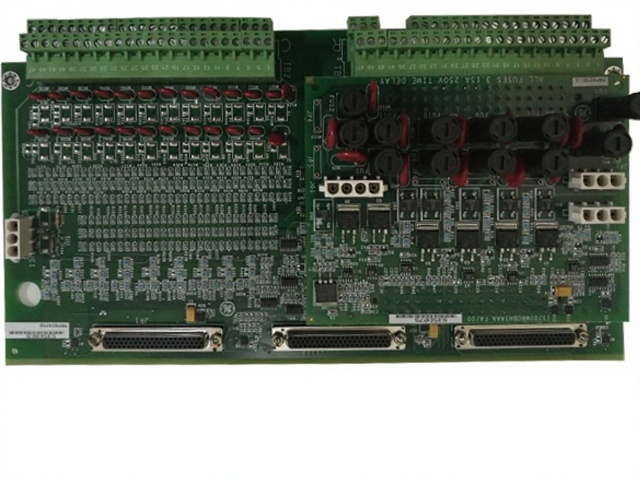

The IS200TTURH1BED Protection Input Turbine Terminal Board is a crucial interface module for GE Mark VI turbine control systems. It captures and transmits critical protection signals to the control system for precise turbine monitoring and safe operation.

Description

The IS200TTURH1BED – Protection Input Turbine Terminal Board is a specialized input interface board designed for GE’s Mark VI turbine control systems. As part of the advanced I/O subsystem, this board ensures reliable signal transmission for turbine protection, acting as a critical link between field devices and the control module.

Built to meet the high standards of GE industrial automation, the IS200TTURH1BED board is engineered to process input signals from various protection devices such as proximity probes, speed sensors, and temperature sensors. These input signals are essential for ensuring real-time feedback on turbine status, enabling immediate corrective actions when operational anomalies are detected.

One of the key functions of the IS200TTURH1BED is to provide isolation and signal conditioning for turbine protection channels. It features multiple input terminals that connect directly to field instruments. The board is capable of supporting high-speed signal acquisition and isolation, ensuring that the control system receives accurate and interference-free data for analysis and decision-making.

This board is often used in gas and steam turbine applications where turbine protection is mission-critical. It supports fault-tolerant designs and integrates seamlessly with the larger Mark VI system, enhancing overall plant reliability. The IS200TTURH1BED also contributes to efficient maintenance practices by offering clear diagnostics and durable components built for long-term performance and industrial environment.

Supplied by Evaflux Private Limited, each IS200TTURH1BED unit is tested for functionality and compatibility before shipping. Whether you are upgrading your existing turbine system or replacing a faulty board, we ensure timely delivery and expert support.

⭐ Key Features:

Designed for GE Mark VI turbine protection systems

High-speed protection input signal processing

Supports proximity probes, speed pickups, and other field sensors

Provides isolation and signal conditioning

Rugged design for harsh industrial environments

Easy integration with existing Mark VI architecture

Supplied and supported by Evaflux Private Limited

📍 Evaflux Private Limited

📞 +91 7303573946

📧 support@evaflux.com

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

Reviews

There are no reviews yet.