Bently Nevada 138607-01 3500/22M Standard Transient Data

Bently Nevada 138607-01 3500/22M Standard Transient Data

Manufacturer : Bently Nevada

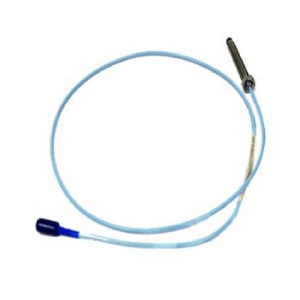

Product No. : 138607-01

Product Type : 3500/22M Standard Transient Data Interface Module

Product Origin:Made in U.S.A

Payment:T/T, Western Union

Weight : 0.82 Kg

Shipping Weight : 3Kg

Description

The Bently Nevada 138607-01 3500/22M Standard Transient Data Interface (TDI) Module is a crucial component for seamlessly connecting the 3500 monitoring system to GE’s System 1 machinery management software. The TDI combines the functionality of a 3500/20 Rack Interface Module (RIM) with advanced communication processors like TDXnet to collect and transfer both steady-state and transient data from critical machinery.

Positioned within the RIM slot of a 3500 rack, the TDI works in conjunction with M series monitors (e.g., 3500/40M, 3500/42M) to continuously gather and transmit waveform data over an Ethernet link to the host software. While the standard TDI captures static data, an optional Channel Enabling Disk allows for the capture of dynamic or transient data, enhancing the system’s data acquisition capabilities.

With improvements over previous communication processors, the TDI ensures smooth integration and optimal data transfer performance. It operates independently of the critical monitoring path, meaning it has no impact on the overall monitoring system’s function, ensuring the safety and reliability of operations.

For Triple Modular Redundant (TMR) applications, the TDI supports monitor channel comparison, providing monitor voting based on predefined settings. It flags discrepancies between redundant monitors, ensuring the highest level of accuracy and system reliability.

Key Features:

Bridges 3500 system with GE System 1 machinery management software

Collects steady-state and transient data for continuous machinery monitoring

Easy integration with 3500/20 Rack Interface Module (RIM) and M series monitors

Optional Channel Enabling Disk for dynamic data capture

TMR version supports monitor voting and fault detection in redundant systems

Ethernet communication for seamless data transmission

No impact on critical monitoring path

Simple installation in Slot 1 of the 3500 rack

RELATED PRODUCTS

Valfux Electric Private Limited is a professional supplier specializing in original brand-new PLC and DCS automation parts from world-renowned manufacturers. Our extensive inventory features trusted brands such as Allen Bradley, Bently Nevada, Honeywell, ABB, GE Fanuc, Siemens, Invensys Triconex, ICS Triplex, Foxboro, Yokogawa, Schneider Electric, HIMA, and more.

Know more about our products and services on evaflux.com and get the update on latest products and services anywhere worldwide. Read more…

-430x287.jpg)

.png)

.png)

.jpg)

.jpg)

Reviews

There are no reviews yet.